Assembly manufacturing for plastic mouldings

Technology

Technology

Individual assemblies for technical plastic parts

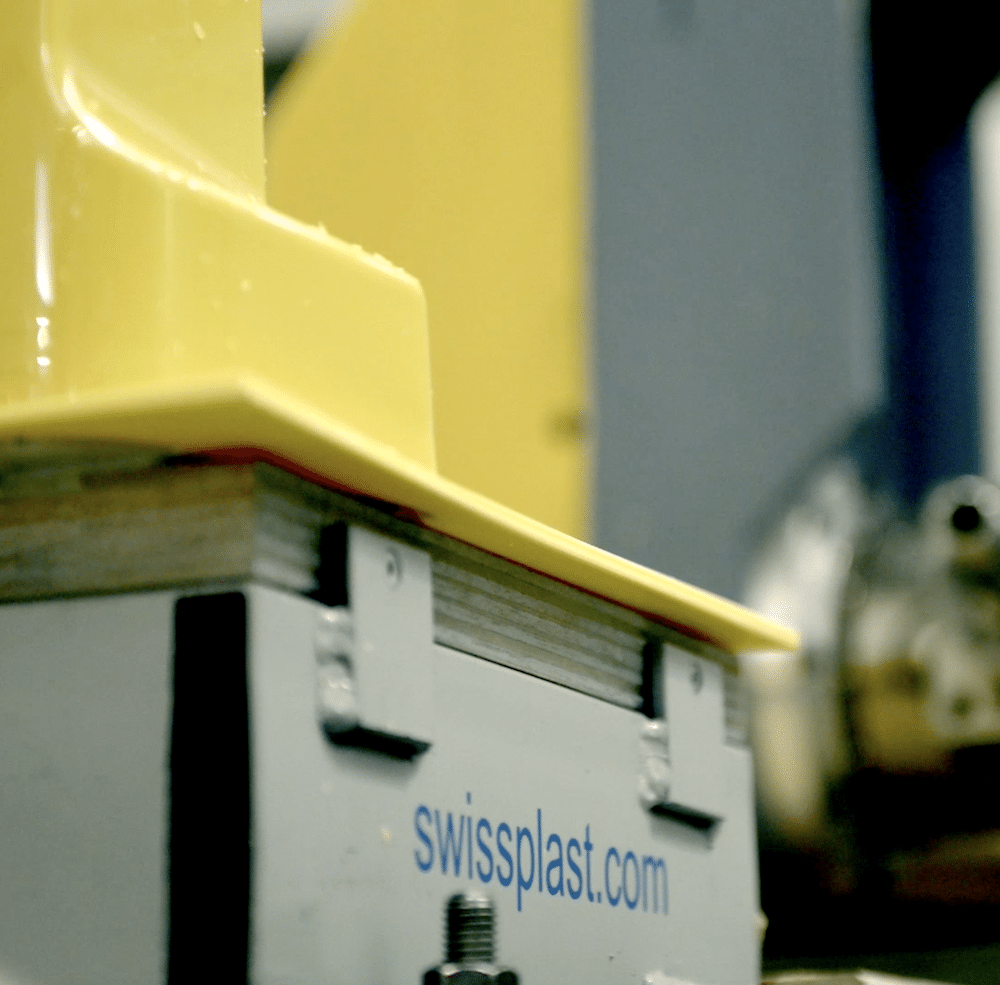

In the swissplast thermoforming process, plastic moulded parts, packaging or tool carriers are produced exactly according to the customer’s specifications and requirements. Assemblies can also be attached to plastic mouldings at the customer’s request. The final assembly can be done by gluing or welding.

Plastic moulded parts are completed during assembly manufacturing – our special solutions

By focussing on plastic deep drawing, we deliberately set ourselves apart from the injection moulding technology commonly used in the industry and also offer CNC milling of plastic only for precision work. Nevertheless, or precisely because of this, we can concentrate fully on individual solutions for your requirements.

Assembly manufacturing is a particularly flexible solution in this respect. In the course of this process, individual parts are turned into workpieces at swissplast that can be processed directly in your company. In practice, we attach assemblies to the moulded plastic parts – exactly according to your specifications and design drawings. Fixing, the final assembly, is done by gluing or welding.

You coordinate this process step with our material specialists in advance. Even if the feather-light plastic moulded part gains weight through the combination with the assembly, the total weight remains low, which is still of great importance in mechanical engineering, for example, but also in e-mobility.

With this special manufacturing variant, assembly manufacturing, we once again underline our focus, which is on the technologically high-quality production of prototypes and small series. This additional swissplast service represents another service component of our company.

Plastics technology from development to deep drawing and assembly manufacturing

Plastics technology is our core competence, for which various technological options used at swissplast. Depending on the area of application, surface and desired colour, we create the optimum production sequence for your requirements and your desired plastic moulded part.

Our consulting and manufacturing services cover the entire production cycle – from development and feasibility checks to design conception and material selection, right through to assembly. Assembly manufacturing enables us to implement complex projects in plastic construction. In doing so, we find the best possible combination of stability, flexibility and functionality of the desired workpiece.

Please feel free to contact us at info@swissplast.com. Our competent team will advise you on your project and explore the feasibility of your idea with the help of assembly manufacturing.

Assembly manufacturing joining techniques for plastic mouldings from swissplast

As a leading company in plastics processing, we offer various joining techniques for assembly manufacturing. Depending on your requirements for the assembly and the materials used, and based on our many years of experience, we select the right joining technique for you.

Offered joining techniques:

Gluing

Welding

Riveting

Screwing

Bonding

and much more

Assembly manufacturing for plastic mouldings from swissplast

swissplast is one of the leading companies for assembly manufacturing with plastic. There are different methods for joining plastics, but also plastics and metal. We offer various joining techniques for assembly manufacturing of plastic mouldings: Bonding, assembly welding and riveting as well as plastic screws, plastic bonding and other techniques. Thanks to our many years of experience in processing plastics, we can select the long-lasting joining technique for you on the basis of the plastic used and the intended use of the assembly. Depending on whether the plastic assemblies are used for the automotive industry, plant construction or sanitary engineering, a different joining technique is recommended. With swissplast, you can be sure that the right joining technology is chosen so that your assembly can withstand a long service life.

Joining techniques for assemblies – all combinations and requirements.

Thermoforming allows us to produce individual plastic mouldings, while CNC milling enables us to customise the components. With assembly manufacturing, swissplast also takes on the next step: the connection of all components. swissplast has virtually no limits in terms of connection techniques or materials. Very extensive assemblies can be produced: Particularly large and complex assemblies are assembled in our specialist department for housing construction. With the help of a special bonding technique (e.g. with two-component adhesives), we are able to bond metal to plastic. In principle, all sandwich components and combinations of materials are possible. Thus, swissplast can join plastic with metal, foam, foam material and also other substances.

Plastic assemblies from swissplast – everything from a single source

As a leading company in the manufacture and processing of plastic assemblies, swissplast can accompany and advise you throughout the entire manufacturing process. Starting with the precise planning of your project and the sounding out of the technical feasibility, through the shaping of the plastic parts by deep drawing and the detail work thanks to CNC milling, right up to assembly manufacturing with the aid of bonding and welding technology, swissplast provides you with everything from a single source. So don’t hesitate to contact us and send us an enquiry about plastic assembly production. Our team will be happy to advise you and make you an offer that meets your requirements and suits you.

Other technologies