Rotary stackable workpiece carriers

Workpiece carriers

Workpiece carrier

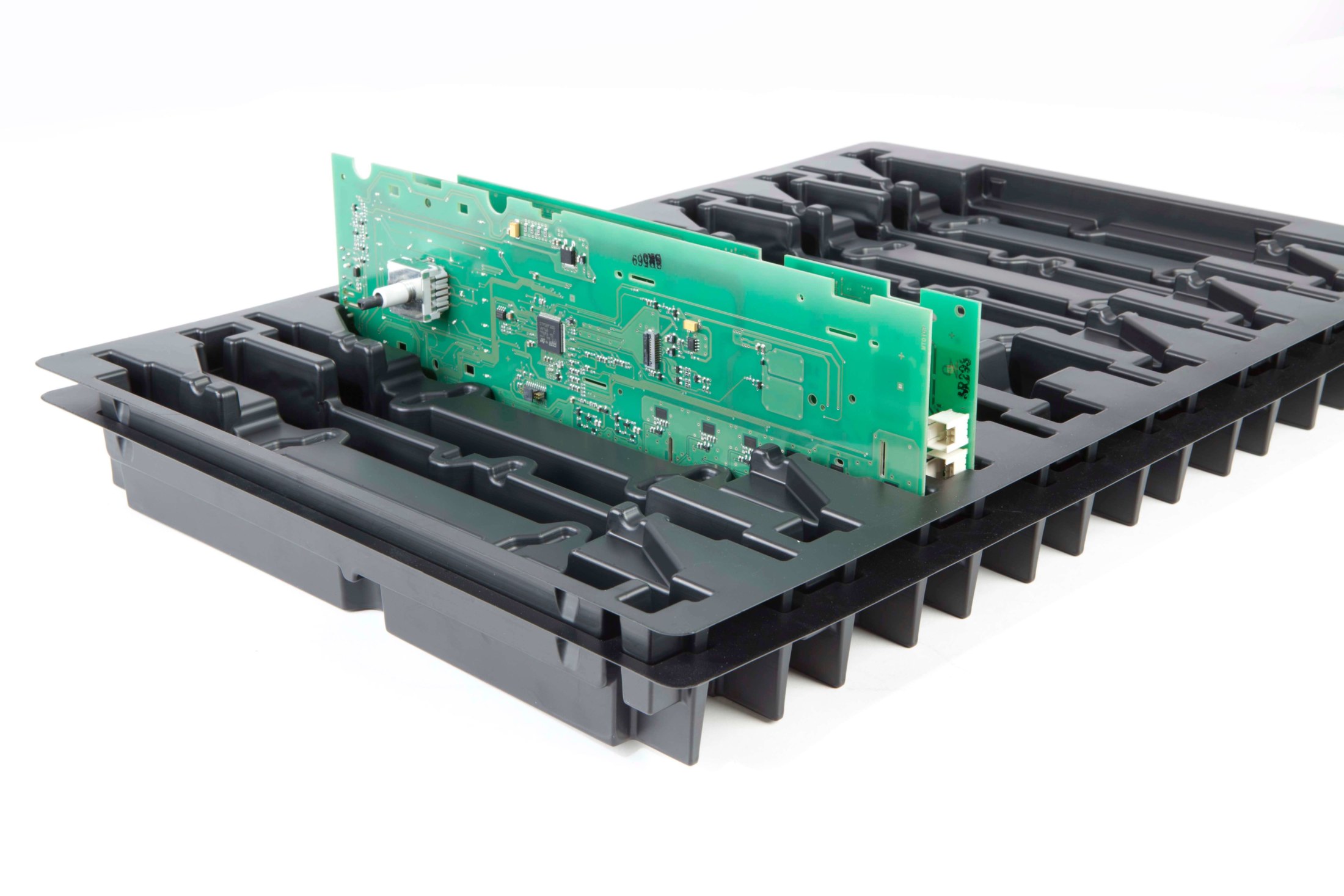

Stackable workpiece carriers with space-saving effect

Rotating stackable workpiece carriers are characterised by the fact that they can be stacked on top of each other when full and lose up to 70 percent of their volume when empty or removed, offset by 180 degrees, due to their nestability.

Rotary stackable workpiece carriers

Nestable and rotatable workpiece carriers such as rotary stacking boxes are of particular importance for all branches of industry. Rotating stacking boxes can be safely stacked on top of each other when full, allowing efficient storage of your products. When you are not using the rotating stacking box, turn it 180 degrees. This gives you a space-saving effect and the nestable containers slide into each other. In this way, up to 70 percent space volume can be saved. Benefit from efficient, space-saving storage both when full and empty.

Nestable workpiece carriers

The term “nestable” is derived from the fact that stackability depends on the orientation of the workpiece carrier or container. In one orientation, the totes can be stacked on top of each other, providing space and protection for cargo. In the other orientation, the boxes slide into each other and can be stored to save space. This means that both options are open to you and the load carriers do not take up much space for their own storage. We can implement a variety of individualisations for you. These include, for example, printing, labelling or RFID tags.

Rotary stackable workpiece carriers from swissplast

- Stackable workpiece carriers with space-saving effect

Stackable in one direction

Turned by 180 degrees, the material carrier nests by up to 70 percent

Additional stacking surfaces prevent the workpiece carriers from sucking into each other

Additional protection through standardised but also contour-appropriate lids

Anti-twist protection

- Visually through a colour stripe

- Mechanically through a non-symmetrical corner, for example

Label pockets (1-, 2- or 3-sided)

Marking of the workpiece carrier

- Lettering inserts in the tool for customer logos, article numbers, etc.

- Pad printing

- Hot stamping

- Screen printing

Identification features can be positioned individually

- Barcode labels

- RFID Transponder

Highest optical requirements

Splash-proof

Multi-part bonded structure

Rotating stackable workpiece carriers – individual and customised

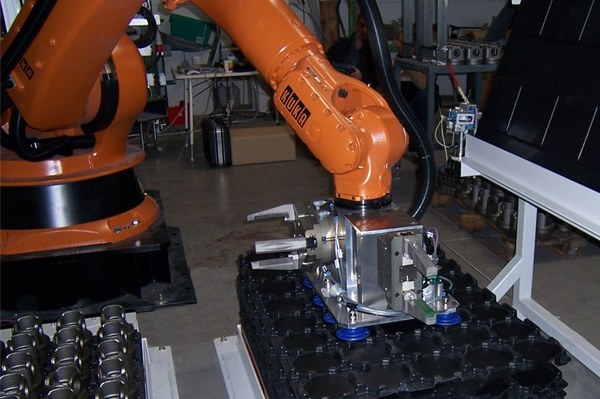

Regardless of which industry you are in, rotary stacking containers are needed and used almost everywhere. The reduction in storage volume is particularly apparent when using conventional stacking boxes without a rotary stacking function. To meet your requirements for the storage volume of the rotary stacking boxes, swissplast manufactures the nestable containers individually and customer-specific. Thanks to the deep drawing process, there are almost no limits to the size and shape of the plastic rotary stacking box. We can produce nestable boxes up to a size of 3 x 2 metres. In addition, the implementation of various individualisation options is no problem thanks to different processes. Label pockets can be added on 1, 2 or even 3 sides and labelling for rotary stackable workpiece carriers is also possible. Such markings are made with the help of pad printing, hot stamping or screen printing. Barcode labels or RFID transponders can also be implemented as identification features. CNC milling allows us to apply your customer logo or other lettering to the nestable containers. Contact our team for rotary stackable workpiece carriers and let us advise you.

Rotating and stacking box from swissplast – the functionality

Nestable containers and turn-stackable workpiece carriers are a good choice for efficient and space-saving storage. The functionality and advantage of rotatable stackable workpiece carriers is that they slide into each other when rotated by 180 degrees, reducing the volume of space by up to 70 percent. To use the safe stacking when filled, turn the nestable box again by 180 degrees, then the turn-stackable workpiece carriers can be placed one on top of the other with a mechanical or optical anti-twist device. The swivel stacking boxes manufactured by swissplast also have additional stacking surfaces that prevent the workpiece carriers from being sucked into each other.

Rotary stackable workpiece carriers of Swiss quality

Customer satisfaction is particularly important to us. That is why we work to the highest standards and with the highest degree of transparency, both in production and during customer communication. Together with our team for rotary stackable workpiece carriers, you work out the dimensions and the choice of plastic for your nestable boxes. The rotary and stackable boxes can be made from all common plastics and there are also almost no limits to the size of our rotary stackable boxes. By using recycled plastic, we can keep the price low on the one hand and conserve resources on the other. Contact our team and take the first step for your nestable boxes in Swiss quality.

Other workpiece carriers