Plastic components in plant and mechanical engineering

Technical components

Technical components

Plastic moulded parts with modern design

More and more often, plastic is being used instead of sheet metal in mechanical engineering. In addition to their extreme resistance properties, today’s plastics have the great advantage that they are not only lighter, but also allow a three-dimensional design. With modern design, manufacturers in plastics processing such as swissplast stand out in the mechanical engineering sector and inspire more and more customers with plastic moulded parts.

Customised plastic components in mechanical engineering

We offer the complete range of grains and colours and already supply many original equipment manufacturers with our moulded plastic components through long-standing customer partnerships. Our customised plastic components impress with their impact and chemical resistance and UV immunity. The plastic moulded parts ensure a longer durability and protect the condition of the machines. In addition, we have enormous design freedom with regard to shape, colour and surfaces. We can also implement all wishes regarding the thickness of the moulded parts, from very thin plastic parts to extremely thick material thicknesses. Our team will be happy to advise you on your specific project requirements.

Plastic components in plant engineering

With our plastic components in plant construction, we have a wealth of possibilities for producing optimally individualised components. Two points are our main focus: On the one hand, we attach great importance to high product quality and thus high stability of the components. This increases the durability of the systems and reduces the susceptibility to maintenance. On the other hand, our working techniques give us great freedom in the area of design. This means that we not only meet the high technical demands, but can also contribute to the economical as well as aesthetic design of your machines. The goal is always a smooth integration of the moulded parts.

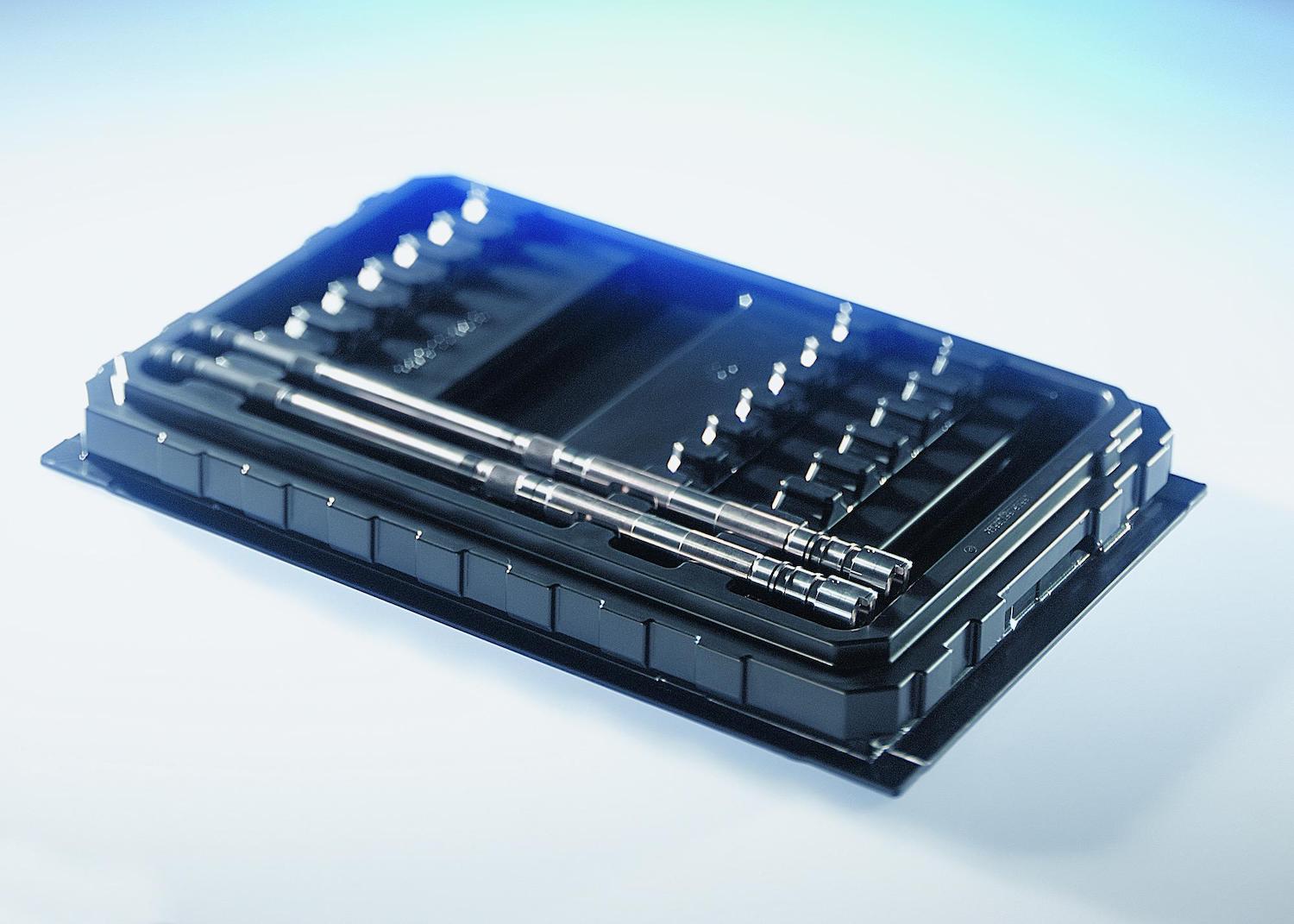

Example: Display for vertical carousel bearing Megamat

Control unit with display and numeric keypad

Certified according to UL 94 VO

Negative tool

Double-shell construction with glued-in turned parts

Material: high-quality ABS, painted with textured varnish

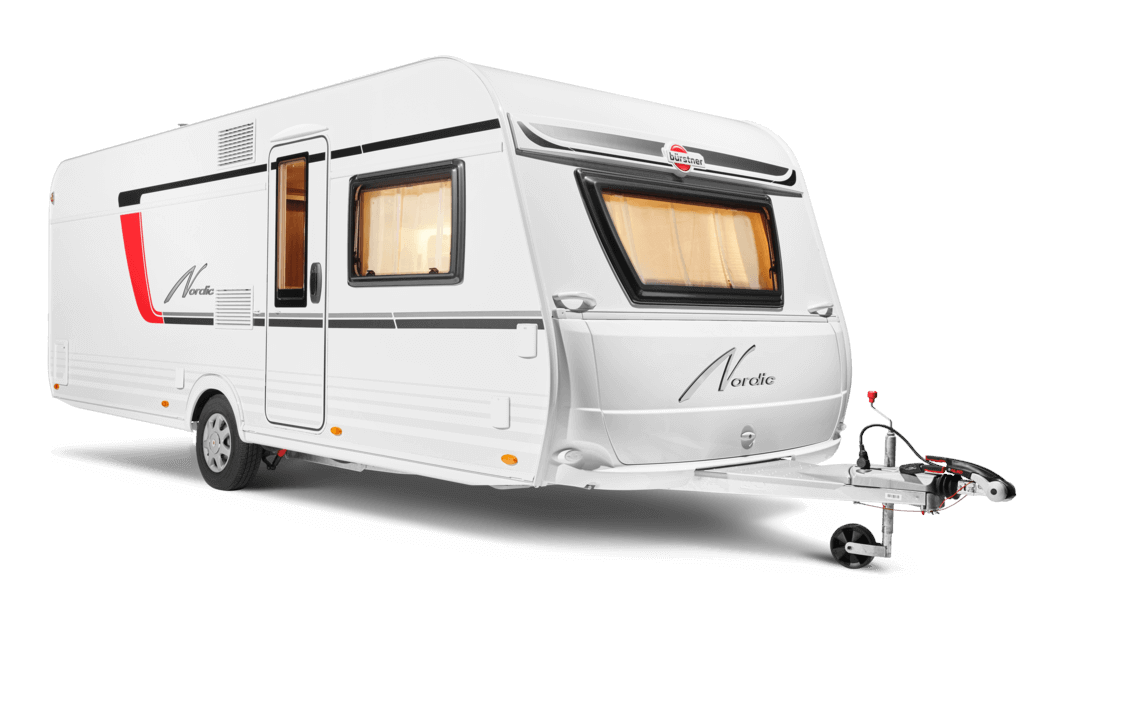

Example: Rotary valve / belt guard

Uniform covers in six different sizes (from 600 x 200 x 100mm to 1250 x 400 x 200mm)

Labelling with UV-stable foils

Material: PS virgin material

UV-stabilised

Electrically conductive

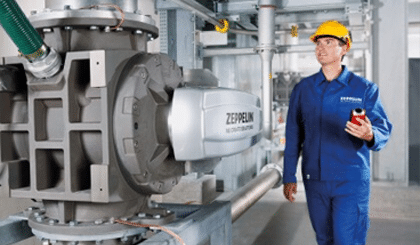

Example: Deep drawing tank for electric potter’s wheel

Large spray tank

Integrated in standing plant

Removable without tools

Water/chemical resistant

Easy to wash

White, smooth surface

Plastic components in plant engineering – the benefits

Plastic components in plant construction and mechanical engineering are important elements today. It is increasingly worthwhile to use plastic instead of sheet metal components or metal parts in the machines. The advantages are obvious: on the one hand, plastic parts in mechanical engineering are lighter than sheet metal parts of the same shape. This promotes lightweight construction and, if necessary, reduces the required engine power of the machine. This change is also relevant for transport. Furthermore, the use of plastic components in plant construction opens up new design possibilities: Moulds can be manufactured even more precisely, which in turn increases the labour and space efficiency of the machines. Furthermore, plastic components in plant engineering have the advantage that they also improve the aesthetics of the machines. Last but not least, plastic components in mechanical engineering are inexpensive to produce, especially for larger runs, and thus reduce the overall costs of product implementation.

Which plastic parts can be manufactured in mechanical engineering?

Thanks to the deep drawing process, there are virtually no limits to the type of plastic components we can produce in plant engineering. In addition to machine cladding, machine covers and machine doors, swissplast manufactures customised machine cladding or plastic housings in the mechanical engineering plastic parts segment, for example. An important aspect for us is the plastic housing design, which you as a customer can determine individually. In addition to the shape for your plastic components in mechanical engineering, you can decide on the material thickness, colour, surface finish and possible integration of other materials. Deep drawing containers and deep drawing parts for use in industrial machines are part of our repertoire. We are also happy to equip machine displays and control consoles with the necessary cladding parts. Please contact us with your individual request, we will be happy to advise you on the implementation in the category plastic components in mechanical engineering.

For which industrial machines do we manufacture plastic parts in mechanical engineering?

Here, too, the list of possible areas of application for our plastic parts in plant engineering is long, because we can implement your plastic components in mechanical engineering from small to large devices and plants: Among other things, we build plastic components for crimping machines, water filters, sorting systems, pallet strapping systems, pottery machines, measuring and testing devices, conveyor machines and dosing machines, brake test stands, industrial vacuum cleaners, storage systems and stacking systems, recycling systems or handling devices. Thus, our plastic components for machines are used in many different branches of industry. What remains the same is the high quality, long service life and great reliability of the parts. Particularly in daily use, industrial machines are exposed to high loads, which must be compensated for by the quality of our deep drawing parts. This reduces the maintenance effort of the machines and they remain active in operational use for longer.

Other technical components