Plastic components for production and automation

Technical components

Technical components

Plastic components for production and automation

swissplast supports your company by manufacturing plastic workpiece carriers, load carriers and trays. These can be integrated into your production to enable automated processes. At the same time, our plastic components impress with the highest product quality, low weight and high stability.

Trays, workpiece carriers and load carriers for production and automation

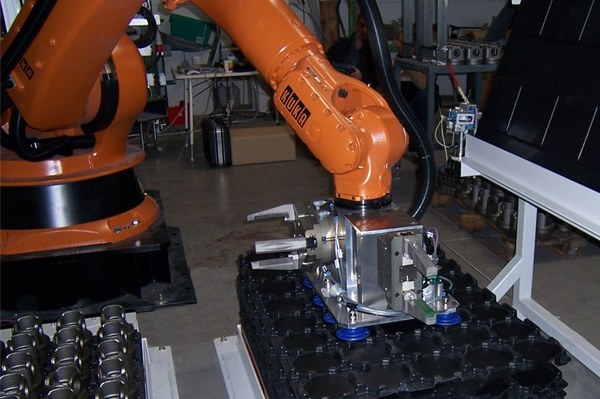

Industrial production facilities are designed for efficiency and time savings. This requires optimum interaction between the individual components. In this area, swissplast supports companies with customised and product-specific plastic load carriers for automated handling. Through the highest precision in the design of our plastic trays, we contribute to a smooth integration into the production environments of our customers. In addition, our plastic trays impress with low manufacturing costs, a long shelf life and their low mass.

Plastic components in industrial production

Our plastic components for automation and production are used in various industries: for example, we equip companies in the automotive industry that use our plastic load carriers in their production lines. Trays made of plastic are also popular in the medical, electrical and metal industries, as they are lighter and cheaper with at least the same stability as metal parts.

Advantages of thermoformed load carriers in production

High repeatability

Cost savings compared to metal workpiece carriers

Low weight

Enormous stability

Precise production

Optimum integration into machine

Many possibilities for individualisation

Types of thermoformed load carriers in production

Plastic trays

Stackable trays

Nestable/twistable trays

Plastic load carriers

Small plastic load carriers

Large load carriers made of plastic

Workpiece carriers made of plastic

Inserts of plastic

Intermediate layers of plastic

Plastic workpiece carriers for production and automation

swissplast is your reliable partner for the production of plastic workpiece carriers for your company. Industry 4.0 is characterised by a growing trend towards automation of production processes. In this context, it is elementarily important to operate production lines efficiently. This is where swissplast comes in and supports you with customised plastic workpiece carriers that hold your products precisely and carry them optimally through the production lines. In this way, our plastic workpiece carriers improve the manual and automated handling of the parts. In this way, our plastic workpiece carriers save time and money in the course of automation.

Trays made of plastic – best quality for your production

The plastic tray is the state-of-the-art solution when it comes to production methods in the industry. In contrast to trays made of metal, plastic trays are on the one hand cheaper to produce and on the other hand have a significantly lower weight. This means that they can be handled more easily by factory personnel. At the same time, there is no loss of stability with plastic trays compared to metal trays: Through the selection of high-quality materials, optimal planning of the production as well as precise implementation, we are able to produce the best possible plastic trays for you cost-effectively, in large quantities and, above all, quickly. Due to a high repetition accuracy in the production of plastic trays, we have an extremely low reject rate, which in turn keeps the price favourable and the production of waste low. Here we have no difficulty in working according to ISO 2768-c and guaranteeing a high fitting accuracy of the parts.

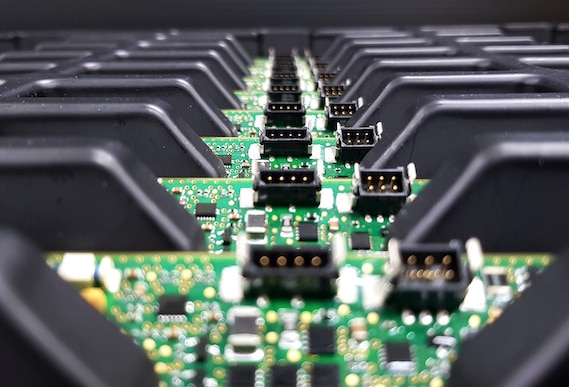

Plastic load carriers – a swissplast speciality

swissplast has been producing plastic load carriers and plastic KLT inserts for leading industrial companies with the greatest possible success for many years. We have a great deal of freedom in the design of the load carriers and can implement your requirements exactly according to plan. On the one hand, this includes the shape of the plastic load carriers, which we can realise product-specifically for your production. On the other hand, you have free choice when it comes to the colour, thickness or printing of the plastic load carriers. Thanks to our assembly manufacturing and twin-sheet production methods, we are also able to integrate other working materials or produce double-walled load carriers. In this way, swissplast supports companies in the automotive industry, medical technology or the electrical industry and contributes to increased efficiency in production with custom-fit plastic load carriers.

Other technical components