Plastic components for medical devices

Technical components

Technical components

Plastic components for medical devices

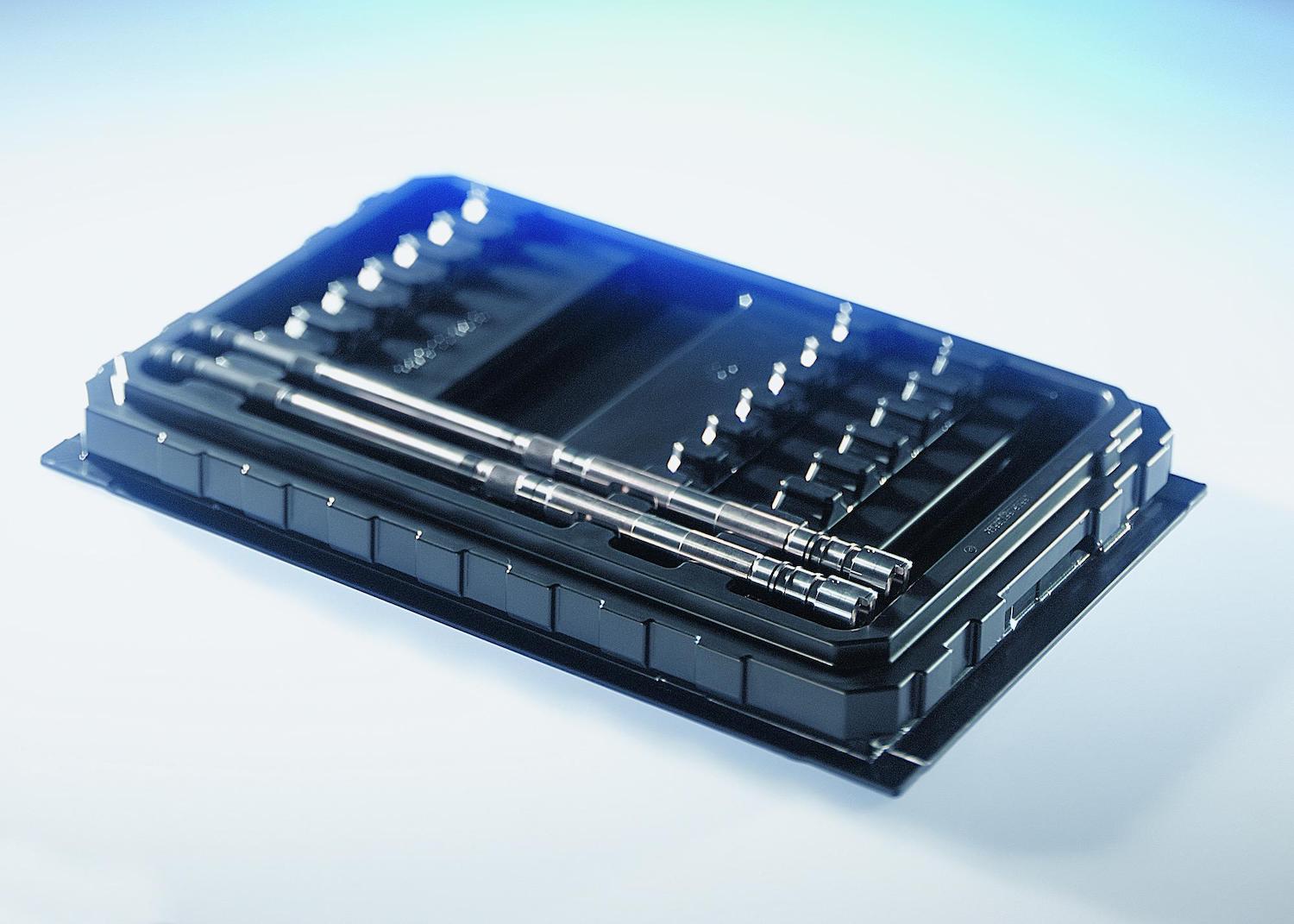

It is hard to imagine modern medicine without moulded medical plastic components. They are not only used in laboratories, but also on medical devices. At swissplast, as a manufacturer of plastic moulded parts for medical technology, we know how to meet the quality and hygiene requirements of the medical sector to the highest standard. The use of robust plastics ensures both customisation and the longevity of, for example, an MRI.

Plastics in medical technology

Plastics have a long history in medical technology. The cladding parts and coverings for medical devices manufactured by swissplast meet all the demands made by medical technology. In addition to their light yet robust nature, medical plastic cladding must also be resistant to chemical cleaning agents, must not cause allergic reactions in patients and must meet the safety requirements of fire protection. swissplast only produces cladding parts for medical devices in accordance with the highest quality requirements. The plastics used are easy and safe to clean, scratch-resistant and durable as well as antibacterial for your protection and that of the patients.

Plastic components for medical devices

The use of plastic components for the cladding and panelling of, for example, MRI and X-ray equipment is particularly worthwhile because of their stability as well as their antibacterial properties. Thanks to swissplast’s many years of experience, we will be happy to advise you on your design wishes and develop custom-fit designs in close cooperation.

Plastic components for other industries

Plastic cladding is also used in physiotherapy and the general fitness industry to ensure safe and hygienic use. swissplast uses PET, ABS and PMMA plastics to manufacture plastic cladding components. We will be happy to advise you on which plastics are best suited to your planned cladding!

Benefits of plastic components for medical devices

Plastic components in medical technology have various advantages:

Individually adaptable

Light

Inexpensive

Durable

Antibacterial

Easy to clean

Adaptable surfaces

Plastic components for medical devices

In MRI as well as in X-ray equipment, the design plays an important role, especially for patients. Good design makes it easier for patients to feel safe during the imaging process. Since medical devices are complex, high-precision machines, plastic coverings must be used to ensure the protection and quality of the equipment. The production of plastics in medical technology therefore follows the highest standards of medical technology, precise manufacturing and strict quality standards. The exact and precisely fitting production of plastic casing for medical equipment is of the highest priority. The plastic components for medical devices produced by swissplast are high-quality and durable formwork.

Plastic cladding for fitness equipment and training machines

Precision manufacturing of plastic cladding for equipment is also in demand in fitness studios and physiotherapy practices. Thanks to our innovative and flexible production methods of CNC milling and plastic deep drawing, we at swissplast have virtually no limits in terms of shape, processing and production. Thanks to high-quality plastics such as PET, ABS and PMMA, we can guarantee scratch-free, easy-to-clean and hygienic surfaces and minimise maintenance work for the devices. At swissplast, we produce plastic cladding for various industries, such as medical technology: plastics in medical technology, plastic components for MRI cladding, plastics for X-ray equipment and plastic cladding for fitness equipment.

Plastic cladding to the highest quality standard

Quality requirements are particularly high in both the fitness industry and especially in medical technology. swissplast uses high-precision and accurate techniques, CNC milling and deep drawing of plastics. The plastics used for cladding are robust and durable to ensure resilience and reduce maintenance to a minimum. In addition, antibacterial plastics can also be used for MRIs and X-ray equipment as required to ensure the highest level of patient protection. Contact us and we will be happy to advise you on the design, manufacture and choice of plastic components for medical equipment.

Other technical components