Plastic components for e-mobility

Technical components

Technical components

Lightweight plastic components for effective e-mobility

swissplast has been manufacturing plastic components for the electromobility industry for many years. The advantages of lightweight, attractive and durable plastic components come into their own very strongly, especially in the e-mobility industry.

Plastic moulded parts for electric vehicles

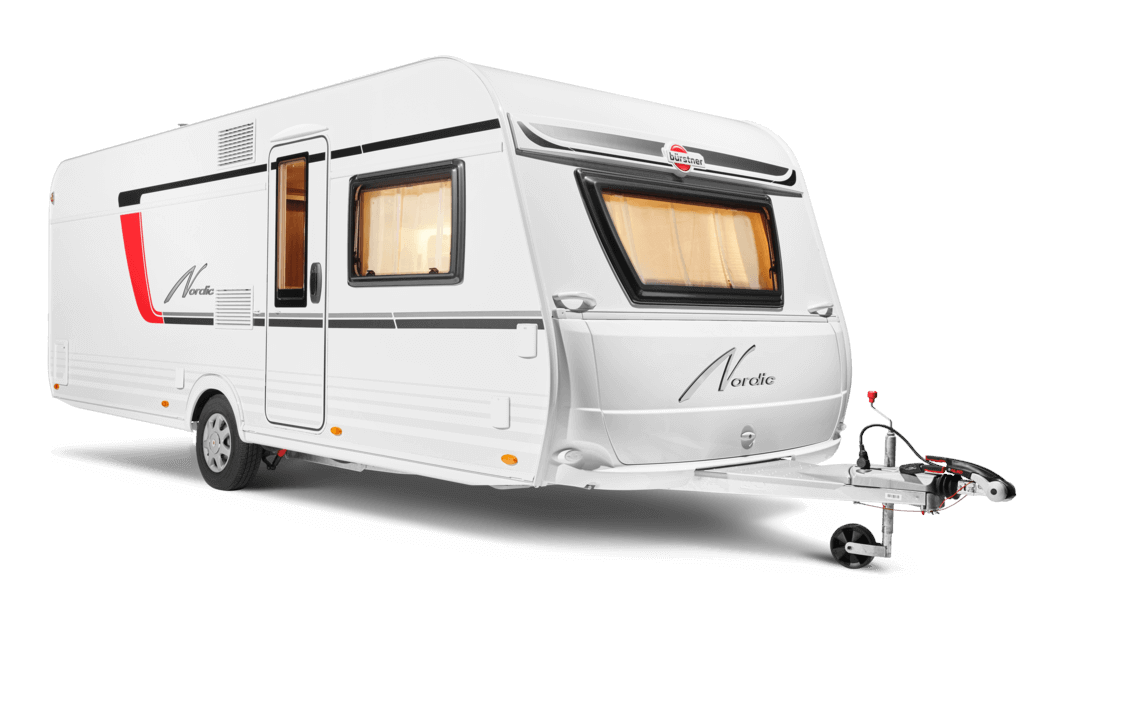

Leading manufacturers count on swissplast know-how for the design of small-series vehicles, luxury cars, leisure cars, low-speed vehicles and electric vehicles. For example, we manufacture trim parts and panels for leisure vehicles. These provide great fun on the road thanks to their low weight and high acceleration. swissplast produces with the latest technologies and manufactures deep drawing parts for interior and exterior applications, also for your electric vehicles. These include bonnets, front bonnets, rear bonnets, side parts, protective parts or covers. Especially for recreational vehicles, the focus is on low mass, but also on particularly high stability of the components.

Plastic parts for electric minibuses

Another application example where swissplast contributes plastic parts in the field of electric mobility is the ABT eT6.1 from the company ABT e-Line. The Volkswagen T6.1, which is refined by ABT e-Line as a model with electric drive, has a grandiose 6.7m3 loading space volume. This is ultimately also made possible by the plastic interior components from swissplast that are installed in the vehicle. Depending on the option, the ABT e-Transporter 6.1 has a range of 121km or 138km with an output of 83kW. Therefore, the eT6.1 is excellently suited as a city power truck, for example in the trade sector, or as a small van for up to nine people.

Advantages of plastic components for emobiles

Reduced weight of the components

Große Flexibilität in der Gestaltung der Komponenten

Low unit price compared to metal components

Extensive assembly manufacturing

Simple combination of plastic and metal components

Integration of other working materials and textiles such as fabric, leather and imitation leather

Torsionally stiff sandwich components through bonding or twinsheet design

Special prints: carbon look, concrete look, aluminium look etc.

We produce these components for e-mobiles, among others

Trim parts / cladding parts

Dashboard

Bumper / Bumper

Kühlerhaube

boot lid / boot floor

Doors / Door trim

Roof parts

Mudguards

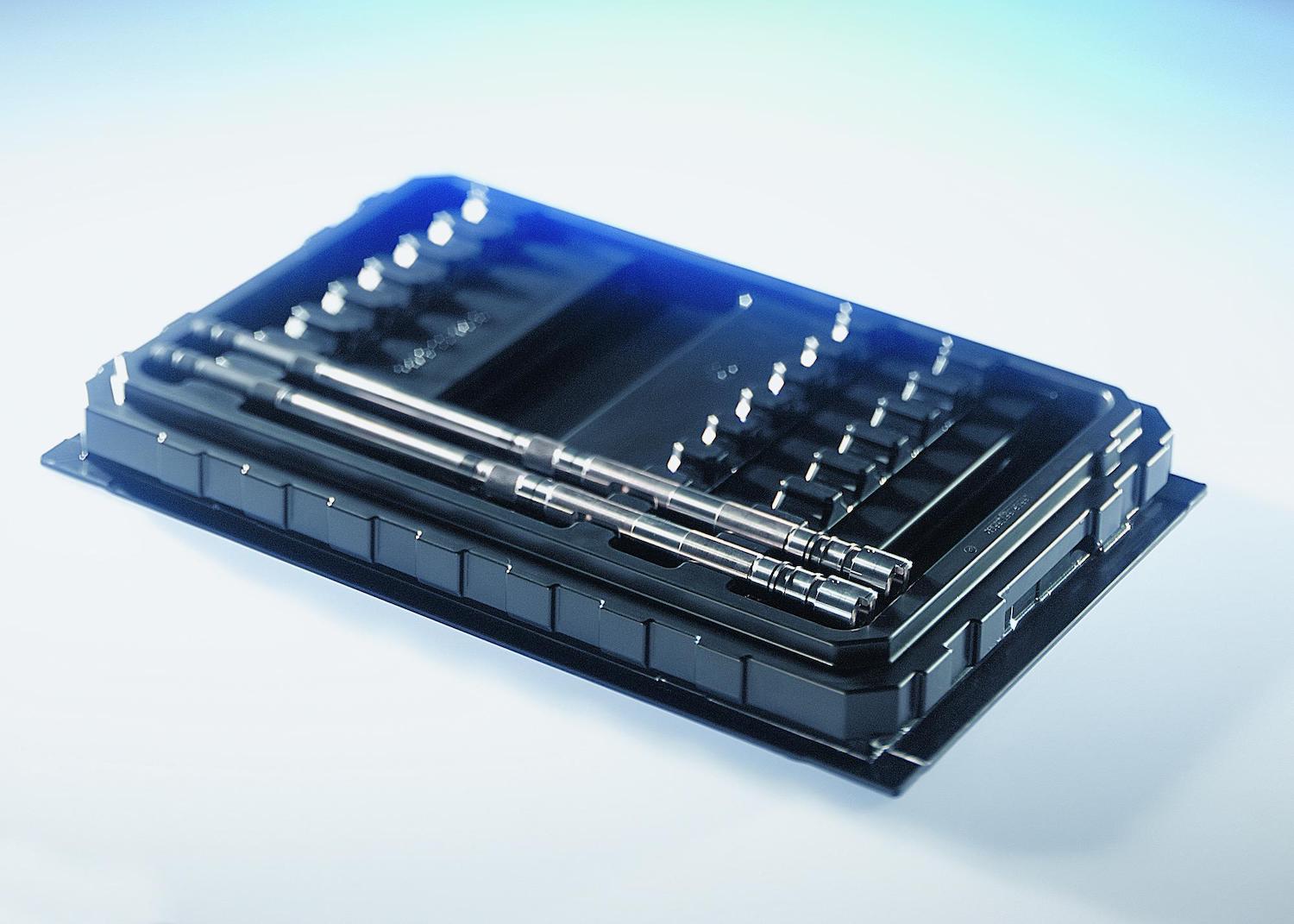

Battery trims / battery covers

Underbody panels / Underbody covers

We manufacture parts for the following vehicles, among others

The range of products for which we produce deep drawing parts is enormous: from classic e-cars to minibuses and Streetscooters, everything is possible. We produce parts for any vehicle with alternative drives. For example, hybrid vehicles, hydrogen-powered vehicles, municipal vehicles, special vehicles, racing vehicles or buggies. There are virtually no limits to the type of vehicle. We would be happy to support you and your project in the production of components for electric vehicles.

Plastic components for emobiles from swissplast

In the context of the energy transition, the trend is moving away from the combustion engine towards electromobility and alternative forms of propulsion. Bit by bit, petrol and diesel cars are being replaced on the roads by e-cars, e-scooters, hybrid vehicles or hydrogen vehicles. In the production of these means of transport, the changed drive conditions also require a rethink in the choice of materials. Plastic components for emobiles are particularly suitable here because they are lighter than metal components of the same size. The weight saving means that the electric motor can be better utilised or energy from the electric battery can be saved. swissplast has been present on the e-mobility market for many years and manufactures, for example, exterior trim, interior trim, underbody covers, underbody protection, roof trim, door trim and other trim parts. We also produce bumpers, shock absorbers, radiator bonnets, mudguards and other plastic cladding parts according to your wishes.

Plastic components for emobiles from swissplast

swissplast is your partner when it comes to components in the field of e-mobility. We equip your Emobil with the right components. Our electric car components cover a wide range of functions: swissplast produces cladding parts, cladding parts in the cockpit, dashboards, shock absorbers, bumpers, radiator bonnets, boot lids, doors, roof parts, mudguards, boot floors, door panels and much more. Even electronic components such as battery covers and battery trims, charging columns and casing or trim for charging columns as well as sensitive parts such as underbody panels and underbody covers present no difficulties for our production. For all e-mobility components, as always, we fully comply with your wishes in terms of shape, colour, thickness, milling work or the integration of other working materials. We have a large portfolio of working techniques to design your product and your emobility component individually according to your specifications.

Emobile parts and components from swissplast

The possibilities and areas of application of the thermoforming process are almost limitless. We produce emobility components for every conceivable type of vehicle: Electric cars, minibuses and minivans represent the target group, which are intended for private use. At the other end of our emobility portfolio are electric car components for utility vehicles such as Streetscooters, municipal vehicles, special vehicles, racing vehicles, prototypes or buggies. Plastic moulded parts are particularly suitable for this type of emobility due to their low weight but high stability. A third area of emobility vehicles that we equip with plastic components are, for example, vehicles with alternative drives, hybrid vehicles or hydrogen-powered vehicles. The combination of low-emission means of transport and CO2-neutral plastic parts is particularly sensible from an ecological point of view. swissplast has been offsetting all emissions produced since 2021 – from raw material extraction to recycling.

Other technical components