Plastic components for caravans

Technical components

Technical components

Plastic components for caravans

Plastic components for caravans are another core competence area of swissplast. Due to their low weight and almost infinite mouldability, thermoformed components are perfect for caravan and motor home manufacturing.

Among other things, swissplast supplies almost all major manufacturers with cover and drawbar covers. We are continuously working on improving design, reliability and durability in the field of plastic moulded parts for caravans.

Plastic moulded parts made to measure for caravans

The established drawbar covers not only impress with their appearance, but also with even greater functionality. Lightweight, custom-made plastic products have long been an important component in the caravan industry. In addition, our drawbar covers have excellent UV resistance, impact resistance and chemical resistance.

Material of the plastic moulded parts

There are hardly any restrictions for us when it comes to the external design of our components for caravans. We have a variety of different working materials at our disposal, which differ in material, thickness, colour or surface finish.

The drawbar covers are available – depending on requirements – in different colours and with different surfaces:

ASA matt black

ABS printed

PMMA back-printed

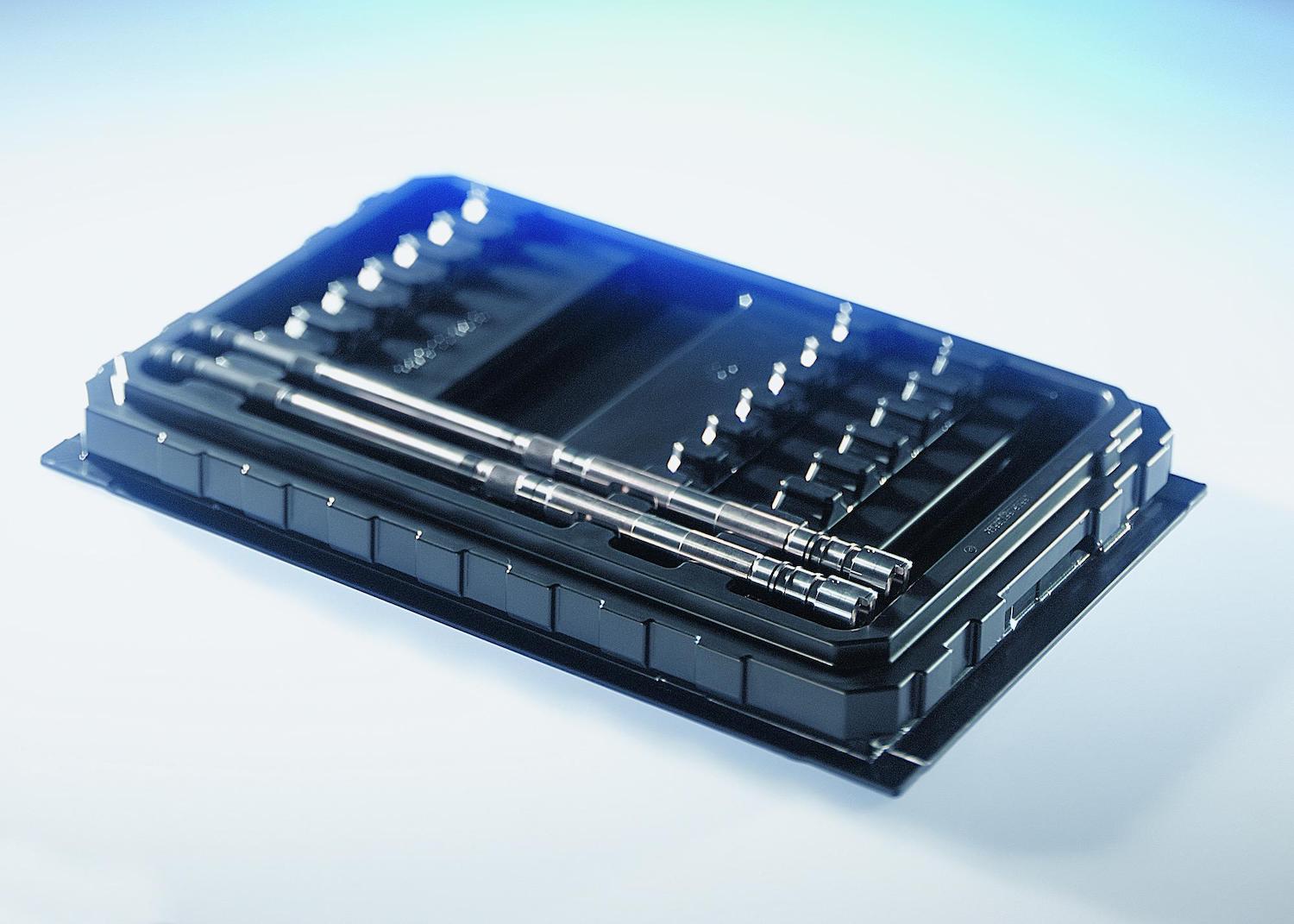

swissplast Premium Cover and drawbar cover

Design surface

UV and weather resistant

Bonded with reinforcing ribs

Multi-part construction

Long service life

Wide range of customisation options

Perfect interaction with metal components

Inexpensive and fast production

Front flap out of plastic

One area of application for deep drawing parts are front flaps and tailgates for caravans. The use of plastic in this area has many advantages: On the one hand, the weight of the flap is reduced compared to a component made of GRP. This means that the lifting mechanism does not have to apply as much force and therefore wears out more slowly. On the other hand, plastic parts can be manufactured very individually as well as cheaply, thus reducing the overall costs of production.

Material of the plastic mouldings

Shower trays, washbasins, shower columns

For wet cells, washrooms and compact bathrooms

Water and chemical resistant

Multi-part construction

- Wide range of options for colour, surface finish or printing

Modifiable through assembly manufacturing

Elegant look

High level of comfort in the caravan

Caravan parts from swissplast

swissplast is one of the world’s leading producers of plastic caravan components. Our deep drawing parts for caravans and motor homes are used both indoors and outdoors and meet the highest quality standards. Our product range is extensive: swissplast already produces light supports, rear light supports, skirts, side skirts, bottle crate covers, drawbar covers, wheel arch shells, wheel arch covers or wheel trims. All caravan components have an enormously high impact resistance, UV resistance as well as weather stability. In addition, the combination of caravan parts made of plastic and other composite materials such as leather, imitation leather or fabric is no challenge, so that we can also ensure a classy look inside the caravan.

Caravan panelling from swissplast

There are virtually no limits to what we can do in the field of caravan panelling: whether it’s interior panelling, fittings, door panelling, seat panelling, ceiling panelling or storage surfaces – we can react flexibly to customer wishes and produce individually matching deep drawing parts for caravans. We also have a high level of expertise in the field of exterior panelling for caravans thanks to years of work. Among other things, we build light carriers, fascias, drawbar covers, skirts, wheel covers or other exterior components. After deep drawing, all our products can be modified as required by CNC milling or assembly manufacturing. These diverse possibilities raise the quality of our plastic moulded parts for caravans to an even higher level.

Caravan wet cell from swissplast

One of our core products that we manufacture for the caravan market is the caravan shower tray. A wet cell in the caravan is a highlight of any caravan interior, as it increases the comfort of the caravan. For a wet cell for caravans, we are happy to supply the required individual components such as washbasins for caravans, shower columns for caravans or shower trays for caravans. Here, too, we guarantee that the caravan parts are manufactured to the millimetre for uncomplicated installation. We also attach great importance to the quality of the materials so that even after many years of intensive use, the wear and tear on the components such as the shower column, wash basin or shower tray is as low as possible.

Other technical components