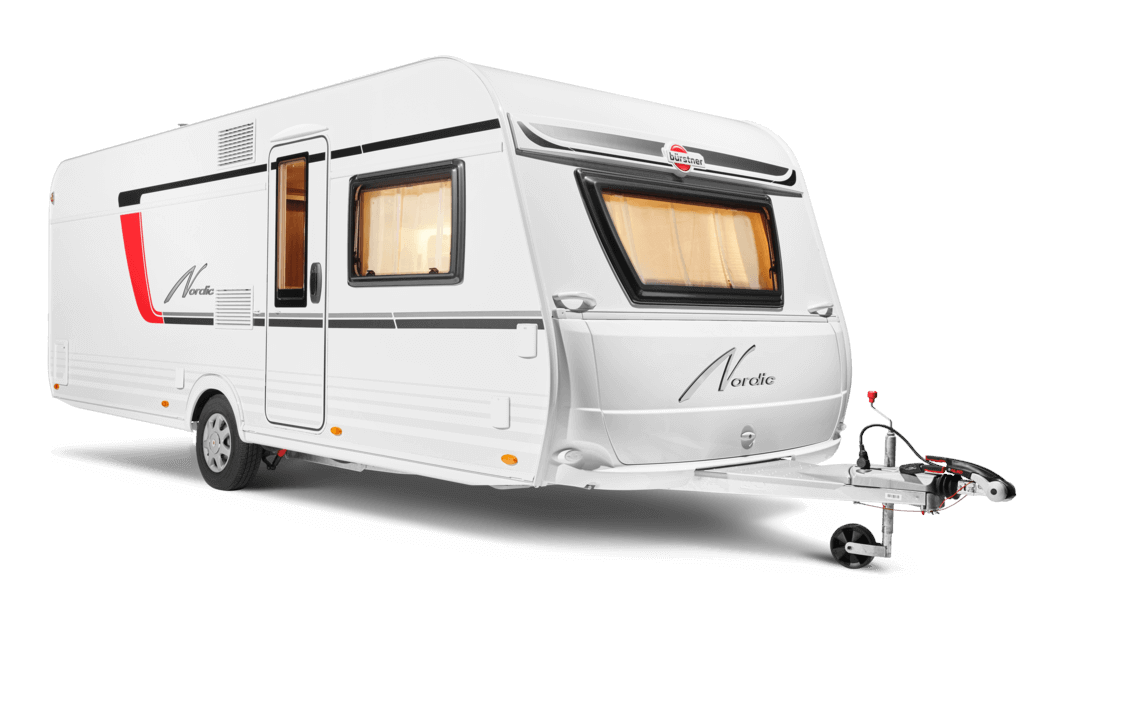

Plastic components for motorhomes

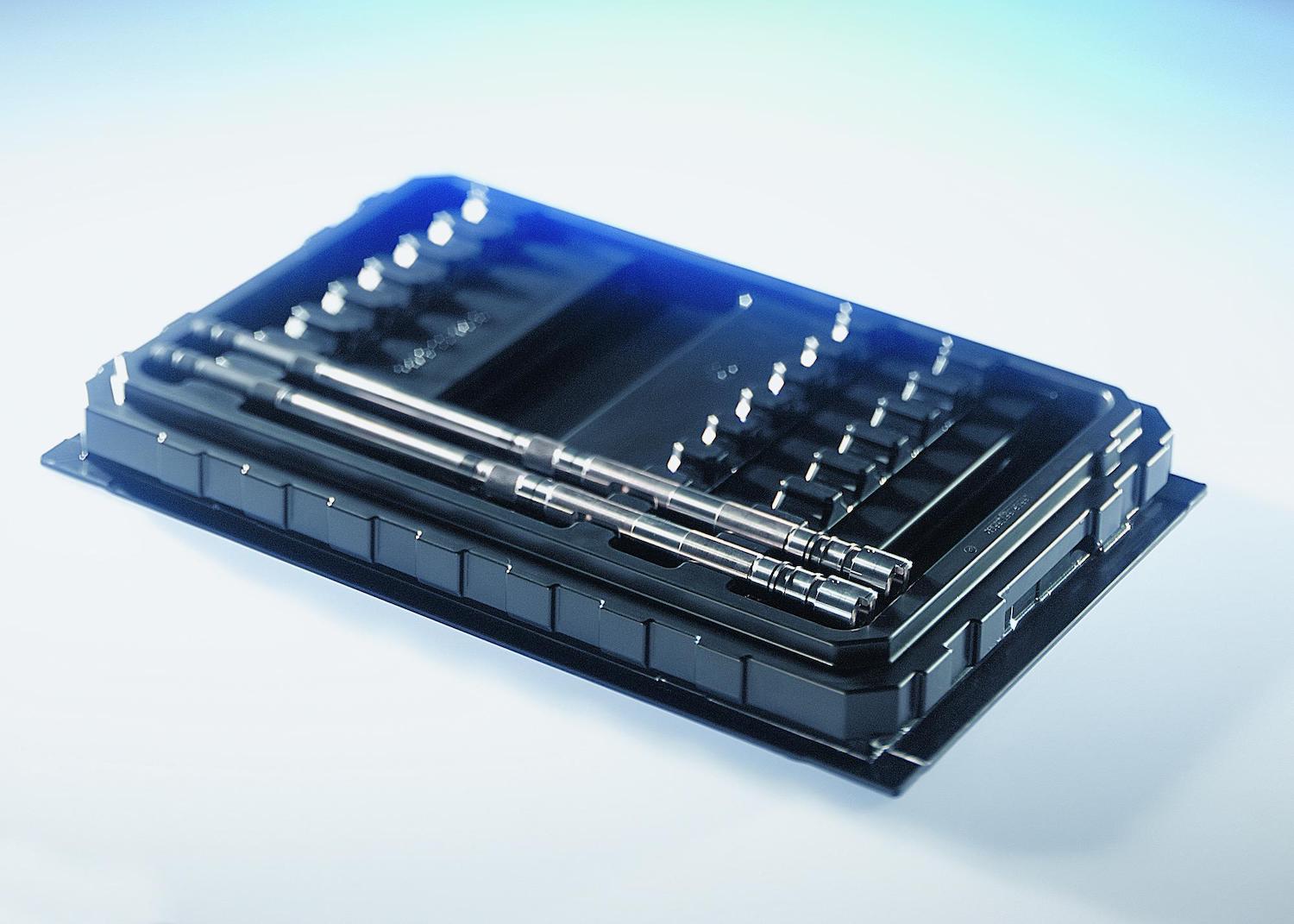

Technical components

Technical components

Plastic mouldings for fully integrated vehicles

Plastic components for motorhomes are another core competence of swissplast. There are many possibilities for thermoforming applications in the caravan and motorhome industry. swissplast supplies practically all major manufacturers in the industry. As a proud market leader, swissplast is continuously working on improving the design, reliability, durability and performance of plastic mouldings for motorhomes.

Plastic components for motorhomes

We have the complete set of suitable solutions exactly for your needs in caravans, caravans and motorhomes. We manufacture plastic mouldings for the interior and exterior of all vehicles in every available colour and grain combination: from interior fittings to door linings, wet cell, dashboard to exterior fittings for alcove linings, rear light carriers, wheel covers and much more.

Made-to-measure moulded plastic components for motorhomes

Lightweight, custom-made plastic products have long been an important alternative to heavy metal parts and offer excellent UV resistance, impact resistance and chemical resistance. With our plastic components for your motorhome, you can ensure that your vehicle remains in better condition and has a longer service life with little effort.

Plastic components for motorhomes from swissplast

For interior use in partially and fully integrated motorhomes

Class A surfaces

UV and weather resistant

Dimensionally accurate to meet the highest requirements for gap dimension tolerances

Sophisticated look and feel

Ready-to-install components / multi-part structure

Certified and tested quality

Material: ABS, ABS/PMMA, PS and PS/PE with TPU coating on one side

Use of special adhesives

Lamination with fabric and leather

Plastic components for rear light carrier in mounted version

Ready-to-install components including luminaires and cable set

Outdoor use on motorhomes

UV and weather resistant

Meets highest optical requirements

Splash-proof

Material: ABS/PMMA silver or ASA black

Multi-part glued superstructure

Wet rooms and shower trays

Ready-to-install components

Use in shower cell/wet cell of motorhome

Material: PS, ABS, ABS-PMMA, PS/PE

- Colour, shape, finish, surface finish as desired

Variable installation options through assemblies, gluing or welding

Motorhome parts by swissplast

swissplast is one of the world’s leading manufacturers of plastic motorhome parts. Thanks to our innovative processes, we are able to produce motorhome parts for your makes quickly, inexpensively and sustainably at the same time. We know virtually no limitations, because our thermoforming method gives us the highest flexibility and we can implement the specifications for your motorhome parts exactly and true to detail. Classics of our production are, for example, products of the groups motorhome trim, rear light carrier, side skirts, wheel arch covers, tow bar cover, wheel housing shell, wheel trim, B-pillar trim, dashboard, door trim, rear spoiler or also bottle crate covers. However, we are not bound to these product groups, our portfolio can easily be expanded to include the motorhome part you require.

Motorhome shower tray by swissplast

Our products in the motorhome shower tray and prefabricated wet cell for motorhomes product groups are also very popular. Shower columns and washbasins are another important component both in the industrial production of motorhomes and in the private conversion of minibuses into motorhomes. We will build you a wet cell for the motorhome or a motorhome shower tray entirely according to your ideas. The production of a wet cell for a motorhome made of plastic is particularly worthwhile due to the material properties. The plastic we use for the wet cell in the motorhome or the shower tray in the motorhome is light, stable and has a long service life even with daily use and daily contact with water – another advantage of plastic components for motorhomes.

Motorhome components from swissplast

The advantages of producing deep drawn parts for motorhomes are obvious: motorhome plastic components are very stable due to their material properties and have a long service life. In addition, they do not corrode or rust when they come into contact with water, which is particularly important when manufacturing a prefabricated wet cell. Added to this is the low weight of motorhome parts made of plastic, which results in a lower overall mass of the vehicle. Our aim is to produce technically flawless deep drawing parts such as prefabricated wet cells that will enhance your products. The parts for motorhomes can be further refined after deep drawing by assembly manufacturing or CNC milling, so that you do not have to carry out any further work steps when installing the respective components for motorhomes and can start directly with the installation.

Other technical components